AAHANA Gifferd Systesms is a leading engineering company. In addition to ASME (U, S, R, NB) we regularly compliance with PED, CRN, CCOE, GOST, DOSH, IBR, AS1210. As a single-source supplier we can provide you with the following services:

With over 48 years of experience, AAHANA Giffard Systems has established a reputation for exceptional quality and dependability at industrial processing sites across the Globe.

We can offer our high quality products from our Germany and India facility, utilizing the latest in CNC Plasma Cutting Machine, CNC Flame Cutting Machine, Tube Bending Machine, 250 Tons press, Boring Mills, Bending Machine for bending sheet metals of thicknesses up to 30 mm, Turning operations up to 1,000 mm in diameter and 4,000 mm in length computer engineering, CAD drawings of all operations and jobs. Our Germany facility has some of the region’s largest manufacturing equipment capable of fabricating high temperature alloys and stainless steels. We have in house designing – engineering – manufacturing –testing – packaging-shipment facilities, saving valuable time and ensuring better control of quality. AAHANA Giffard Systems offers services to suit each customer in quality, service and price.

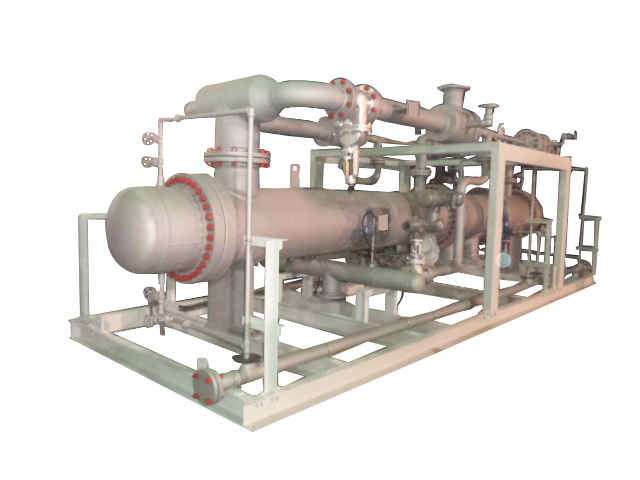

Our trained engineers, using the latest computer design tools, with complete understanding of the fundamentals of design, and over 100 years of combined experience, translate the proposal into a design that meets all the latest ASME and TEMA standards and utilizes to the fullest the modern production facilities available to fabricate the heat exchanger, Condenser and other Ejector Vacuum systems.

We are not Six Sigma company, we try to work very close to “zero defects” as much as possible and this practice has changed the DNA of AAHANA Giffard Systems — it is now the way we work — in everything we do and in every product we design.

Our experience is vital to everything we do. Whether we're designing, assembling or simply working with you to discover the right solution for your company's needs, we're always applying our extensive knowledge and experience to the task at hand. As industry experts, we offer unrivalled quality and service to our customers.

All our products, whether a single stage Ejector or Multi stage Vacuum system (SJAE), can be supplied with full documentation and certification and our professional, on-site assembly team ensures that all products are delivered to our customers fully tested and ready to use. We constantly review our internal procedures across all core business functions including customer service, sales and finance to make sure we deliver the best service possible.

Using the knowledge and creativity of our in-house design team, we're able to offer bespoke solutions tailored to suit your needs. We've designed custom builds for a wide range of industries and applications requiring the precise power and action that only a customised product can give, whether we've built a Heat Exchanger or an entire Condensing system, we're able to supply all our products with full documentation and certification, ensuring you meet your stringent safety requirements. No project is too large, or too small, with a range of customized options available.

Each of our bespoke solutions is carefully project managed with customer input sought at all key stages. Our strict quality control procedures ensure that every specialist application involves the customer at all stages: consultancy, design, review, approval, prototype, test and customer inspection. We offer full after-sales support, ranging from technical advice to engineering assistance, with a skilled team always on hand to assist with your queries. We meet clients’ specific needs with high performance product and solution for each market and need.

This is thanks to the clear vision, its solid and reliable foundation and a team of experts with unrivalled experience in developing innovative concepts. With over 48 years experience in Ejector Vacuum business we provide highly efficient & reliable solutions that meet your requirements.

Maintenance programs, while necessary, cause delays and reduced production for our customers. That is why our highly trained maintenance teams are always on standby and ready to be deployed at short notice. We carry a wide range of stock including tube, plate , flanges, manual valves and associated materials for heat exchangers and Ejectors. This is necessary to maintain our fast turn-round and give us the leading edge.

With over 48 years experience, we have learned a great deal about the materials needed to create industry-leading products. The various materials used in our products call for skilled technicians, such as those you will find at AAHANA Giffard systems. With our patented innovations and industry-proven Ejector Vacuum systems we use our knowledge and experience to help our customers use less energy, produce less waste, increase product quality and improve productivity.

To integrated equipment to business and industry worldwide that provides cost reductions with attractive payback periods while enhancing the environment and negating environmental liabilities.

AAHANA Giffard systems are able to offer our customers true global support thanks to our production capacity in Germany, UK and India and sales/rep offices around the world in Germany, UK, Russia, USA, India, Canada, Singapore, Indonesia, Malaysia, Philippines, Turkey, Brazil, Argentina, Mexico, South Korea, Japan, Taiwan, UAE, Nigeria, Ghana, Australia and South Africa.

AAHANA Giffard systems will select suppliers who offer goods and services that are of the highest quality and offer a full range of support at a competitive price and optimal service. New business will be awarded only after a complete supplier evaluation.We employ this policy to ensure the best use of suppliers' time and availability of the appropriate purchasing personnel.

At AAHANA Giffard systems, we take pride in our strong ethical business values and work hard to ensure that we offer products and services that are based around them.

As a part of our corporate responsibility, we: